Vinidex products are carefully designed from start to finish with a high focus on sustainability. Our manufactured PVC pipe, fittings, PE and PP pipe are made to the best environmental standards.

Vinidex products are carefully designed from start to finish with a high focus on sustainability. Our manufactured PVC pipe, fittings, PE and PP pipe are made to the best environmental standards.

All Vinidex manufactured pipe and fittings are compatible with drinking water

All Vinidex manufactured PVC, PE, PP pipes and fittings can be used safely when in contact with drinking water, as they are specifically tested to AS/NZS 4020. Download our statement of suitability.

Vinidex manufactured PVC pipe and fittings are Best Environmental Practice PVC (BEP PVC)

Download the Vinidex BEP PVC certificates

-

What is BEP PVC?

The Best Environmental Practice standards cover criteria which addresses the environmental impacts associated with the manufacture and end life management of PVC products.

-

Why BEP is important?

The Best Environmental Practice (BEP) PVC criteria were originally determined by the Green Building Council of Australia in consultation with industry bodies and were subsequently included in Australian product standards for PVC pipes and fittings. The criteria cover the environmental impacts and health risks associated with the manufacture and end life management of PVC products used in buildings. They include strict minimum compliance requirements for PVC supply chain constituents, PVC resin production, PVC product manufacture and end of life management – recycling.

Vinidex is proud to manufacture PVC pipes and fittings in Australia to the BEP PVC requirements.

-

Vinidex PVC pipe and fittings are made to the highest standard

- Vinidex PVC pipe and fittings are rigid and have no phthalates

- No heavy metal stabilisers. Therefore, no lead, cadmium or mercury-based compounds are added to Vinidex PVC pipe or fittings.

- Australian PVC pipe standards set the lowest VCM thresholds of any National Standards worldwide at 1ppm

- No dioxins in PVC pipe

- Vinidex has responsible sourcing of raw materials, best practice manufacturing, fully independent third party certification compliance and easier identification of compliant products.

![]()

Vinidex plastic pipes are long life, not single use.

Vinidex plastic pipes are long life, not single use. Vinidex products are designed for long life and are not single use. This long life comes from the durability of the plastic polymers combined with the engineered design of the pipes and fittings products.

Vinidex products are designed for long life and are not single use. This long life comes from the durability of the plastic polymers combined with the engineered design of the pipes and fittings products.

Water supply and drainage for agriculture – crops, pastoral for livestock, food growth, parks and recreation to provide:

Water supply and drainage for agriculture – crops, pastoral for livestock, food growth, parks and recreation to provide: Facilitate the production of minerals which contribute to critical products and infrastructure in our industrialised world.

Facilitate the production of minerals which contribute to critical products and infrastructure in our industrialised world.

Vinidex pipes and fittings are safe for carrying drinking water and don’t corrode

Vinidex pipes and fittings are safe for carrying drinking water and don’t corrode Vinidex plastic pipes and fittings and manufacturing raw materials don’t pollute our waterways and oceans.

Vinidex plastic pipes and fittings and manufacturing raw materials don’t pollute our waterways and oceans. Vinidex has been manufacturing plastic pipes and fittings for over 60 years in Australia and led the way in the development of advanced material-efficient products such as Supermain® PVC-O.

Vinidex has been manufacturing plastic pipes and fittings for over 60 years in Australia and led the way in the development of advanced material-efficient products such as Supermain® PVC-O. Vinidex PVC, PE, PP pipes and fittings are fully recyclable

Vinidex PVC, PE, PP pipes and fittings are fully recyclable Lower Carbon Footprint than alternatives

Lower Carbon Footprint than alternatives Many people do not realise that Australian product standards prohibit the use of external recyclate in some products, such as certain pressure pipes. Vinidex will therefore not use external recyclate in these products.

Many people do not realise that Australian product standards prohibit the use of external recyclate in some products, such as certain pressure pipes. Vinidex will therefore not use external recyclate in these products.

Developing piping systems that improve industry solutions and provide a sustainable and innovative approach to existing pipeline needs.

Developing piping systems that improve industry solutions and provide a sustainable and innovative approach to existing pipeline needs. Material efficient products reduce carbon footprint by using less material to achieve the same or superior custom engineered performance outcomes. This produces savings in the use of raw materials, energy, transportation and installation costs. Vinidex material efficient products are highlighted below.

Material efficient products reduce carbon footprint by using less material to achieve the same or superior custom engineered performance outcomes. This produces savings in the use of raw materials, energy, transportation and installation costs. Vinidex material efficient products are highlighted below.

Vinidex Supermain® oriented PVC pressure pipe is the most technically advanced PVC pipe available. Molecular orientation means PVC-O is double the strength of PVC-U or PVC-M material with significantly improved impact and point load resistance. The higher strength means around 50% less material is required for the same pressure class, reducing carbon footprint and giving the lowest embodied energy of any reticulation pressure pipe system (confirmed by the CSIRO). Supermain® is the high-performance, cost-effective pipe material choice for pressure applications.

Vinidex Supermain® oriented PVC pressure pipe is the most technically advanced PVC pipe available. Molecular orientation means PVC-O is double the strength of PVC-U or PVC-M material with significantly improved impact and point load resistance. The higher strength means around 50% less material is required for the same pressure class, reducing carbon footprint and giving the lowest embodied energy of any reticulation pressure pipe system (confirmed by the CSIRO). Supermain® is the high-performance, cost-effective pipe material choice for pressure applications. Vinidex Hydro® PVC-M is a modified PVC suitable for pressure applications for potable water, irrigation, fire fighting and some general industrial applications, with enhancements in fracture behaviour and hydraulic efficiency. Depending on size and class, Vinidex Hydro® offers weight savings in excess of 10% over normal PVC.

Vinidex Hydro® PVC-M is a modified PVC suitable for pressure applications for potable water, irrigation, fire fighting and some general industrial applications, with enhancements in fracture behaviour and hydraulic efficiency. Depending on size and class, Vinidex Hydro® offers weight savings in excess of 10% over normal PVC. Vinidex Corflo® is high-performance double-wall PVC pipe with a smooth internal bore and corrugated exterior for electrical and communications applications

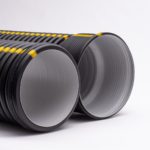

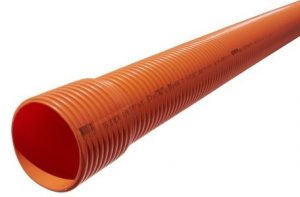

Vinidex Corflo® is high-performance double-wall PVC pipe with a smooth internal bore and corrugated exterior for electrical and communications applications Vinidex twin walled corrugated StormPRO® stormwater pipe is a materially efficient and sustainable solution for stormwater and drainage applications in road, rail, infrastructure, mining, rural and land development.

Vinidex twin walled corrugated StormPRO® stormwater pipe is a materially efficient and sustainable solution for stormwater and drainage applications in road, rail, infrastructure, mining, rural and land development. Vinidex products are carefully designed from start to finish with a high focus on sustainability. Our manufactured PVC pipe, fittings, PE and PP pipe are made to the best environmental standards.

Vinidex products are carefully designed from start to finish with a high focus on sustainability. Our manufactured PVC pipe, fittings, PE and PP pipe are made to the best environmental standards.