PE Below Ground Installation

To be read in conjunction with AS/NZS 2033 and AS/NZS 2566.2

Preparing the Pipes

Before installation, each pipe and fitting should be inspected to see that its bore is free from foreign matter and that its outside surface has no large scores or any other damage. The limit for allowable damage to the external surface away from the sealing surfaces is 10% of wall thickness. Kinked sections of pipe shall not be installed, re-rounded or repaired. Damaged sections of pipe may be cut out and the remaining pipe installed.

Preparing the Trench

All other services must be located (such as telephone conduits, gas, water mains, sewers, electrical conduits, and cable TV conduits) in the area of the PE pipeline before any work commences. This may require some localised excavation, and all safety requirements must be observed.

When pipes are installed on the natural surface, the pipeline route must be clear of obstructions and where required, sufficient space must be allowed for expansion/contraction movement.

PE pipes may be joined outside the trench, allowing narrower trenches and consequent reduced excavation cost.

PE pipes have a density less than that of water and may float if water is present in the trench, and the pipes are not restrained. Trench excavations need to be kept free of water, and if necessary, dewatering equipment installed.

Trench Widths

The Table below lists recommended trench widths. These values are consistent with the principles that trench width should be as narrow as possible in order to minimise external loads and installation costs, whilst also affording sufficient space to provide the specified compaction.

The actual trench width adopted will be influenced by the soil conditions, the jointing systems, and whether joints are made in the trench.

Recommended Trench Widths

| Pipe Diameter | Minimum Trench Width |

| (mm) | (mm) |

| 16 to 63 | 150 |

| 75 to 110 | 275 to 310 |

| 125 to 315 | 325 to 715 |

| 355 to 500 | 755 to 800 |

| 630 to 710 | 930 to 1010 |

| 800 to 1000 | 1100 to 1700 |

Poor soil conditions may necessitate a wider trench to accommodate support structures or dewatering equipment, and the ready removal of this equipment after the pipes have been laid. Where such supports are used, they must be removed with care, in order to prevent disturbance of pipe, bedding or trench walls.

Pressure pipes, especially in rural areas, may be installed in narrow trenches with sufficient space to allow the backfill of the trench. No additional compaction may be necessary, and the natural soil consolidation allowed to occur with time. Where PE pipes are installed with other services in common trench situations, the trench width may be specified by Local Authority regulations in order to permit later maintenance activities.

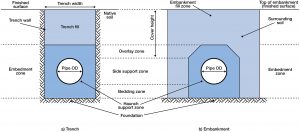

Trench Depths

The trench depth shall allow for the required grade of the pipeline, depth of bedding material and sufficient cover over the top of the PE pipes for adequate protection from external loads, third party damage, and construction traffic. The recommended minimum cover over Vinidex PE pipes is given in the Table below.

Minimum Cover

| Loading Condition | Cover, H |

| (mm) | |

| Not subject to vehicular loading | 300 |

| Subject to vehicular loading- (a) no carriageways; (b) sealed carriageways; (c) unsealed carriageways |

450 600 750 |

| Pipes in embankments or subject to construction equipment loading | 750 |

Trench walls in poor soil conditions may need to be excavated in steps, or be battered, to prevent collapse of the trench wall materials.

For embankment installations, a sub trench may be excavated once the embankment has been partly built up, in order to help protect the PE pipes from construction vehicles, and also lessen the external loads acting on the pipe.

Bedding Material

The excavated trench floors must be trimmed even, and be free from all rocks, and hard objects and be able to provide continuous support for the pipes.

In poor soil conditions, an additional layer of imported bedding material may need to be introduced, and a geofabric restraint of bedding/backfill material may be required.

The bedding materials used in both trench and embankments shall follow the guidelines of AS2566.2, and should be one of the following:

- Sand or soil, free from rocks greater than 15 mm in size.

- Crushed rock, gravel, or graded materials of even grading with a maximum size of 15 mm.

- Excavated material free from rocks or organic material or vegetable matter that will affect embedment material performance.

- Controlled low strength materials (CLSM).

Excavated materials are often used for pressure pipelines and in rural areas. However, in areas of high loading, such as under roads, imported materials may need to be used.

In the majority of PE pipe applications, a minimum of 75 mm of bedding material is used in both trenches and embankments in soil excavations. For excavations in rock, 150 mm bedding depth may be required.

Where fittings or mechanical joints are used, the bedding material may need to be excavated to prevent point loading. All pegs and markers used in aligning and levelling the pipes must be removed from the trench floor prior to bedding materials being placed.

Side Support and Overlay

PE pipes act as flexible pipes to resist external loading, and the side support materials must be evenly added to the same compaction standards as the bedding materials so that the installed PE pipe is not disturbed.

Side support materials should be built up equally on both sides of the pipes in layers of 150mm and compacted evenly to the TEPPFA or AS/NZS 2566 design level. The side support materials must be carefully placed around the haunches of the pipes to ensure that the PE pipes are evenly supported.

The overlay materials should be built up in compacted layers until the overlay material is to a level of a minimum of 150 mm above the top of the PE pipes. Large diameter (450 mm and above) PE pipes require the overlay materials to be carried to a cover of 300mm above the top of the PE pipes.

Detector tapes, or marker strips, should be laid on top of the overlay once a layer of 150mm soil has been compacted.

Vibrating plate compactors must not be used until there is a 300mm layer of overlay soil over the crown of the PE pipe.

Trench Fill

Where the settlement of the finished surface is not important, the remainder of the trench, or embankment fill may be made with the previously excavated native materials. These must be free from large rocks, vegetable matter, and contaminated materials, and all materials must have a maximum particle size less than 75 mm.

Where PE pipelines are installed in areas with high external loads or where the surface is to be paved and the settlement of the finished surface is to be controlled, then the backfill materials must be capable of being compacted to the specified density.

Compaction Standards

It is essential that the TEPPFA or AS/NZS 2566 compaction levels are attained, as PE pipes behave as flexible structures. Large diameter PE pipe installations may require the compaction at each stage of the installation to be confirmed by test.

Where high external loads are encountered, or where it is not possible to attain the required level of compaction in the side support materials, a mixture of sand/cement in the ratio of 14:1 may be used in the side support zones.