PVC Above Ground Installation

To be read in conjunction with AS/NZS 2032 and AS/NZS 3500.

General Considerations

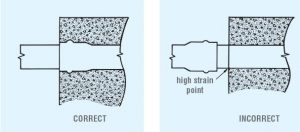

In above ground installations, pipes should be laid on broad, smooth bearing surfaces wherever possible to minimise stress concentration and to prevent physical damage.

PVC pipe should not be laid on steam lines or in proximity to other high temperature surfaces.

Where a PVC pressure pipeline is used to supply cold water to a hot water cylinder, the last two metres of pipe should be made of copper and a non-return valve fitted between the PVC and copper line to prevent pipe failure. Refer also to AS/NZS 3500.4.

Where connections are made to other sections or to fixtures such as pumps or motors, care should be taken to ensure that the sections are axially aligned. Any deviations will result in undue stress on the jointing fittings which could lead to premature failure. If a pipeline is subjected to continuous vibration such as at the connection with a pump, it should be connected by a flexible joint or, if possible, the system should be redesigned to eliminate the vibration.

The pipe must be adequately supported in order to prevent sagging and excessive distortion. Clamp, saddle, angle, spring or other standard types of supports and hangers may be used where necessary. Pipe hangers should not be over-tightened. Metal surfaces should be insulated from the pipe by plastic coating, wrapping or other means.

A build-up of static electricity on the outside surface of PVC pipes can occur. Where there is a risk of explosion, such as in some mining applications, safety precautions may be required.

Brackets and Clips

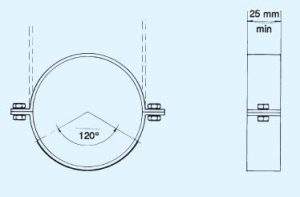

For either free or fixed pipeline supports using brackets or clips, the bearing surface should provide continuous support for at least 120° of the circumference.

Straps

Metal straps used as supports should be at least 25 mm wide, either plastic-coated or wrapped in a protective material such as nylon or PE sheet. If a strap is fastened around a pipe, it should not distort the pipe in any way.

Free Supports

A free support allows the pipe to move without restraint along its axis while still being supported. To prevent the support from scuffing or damaging the pipe as it expands and contracts, a 6 mm thick layer of felt or lagging material is wrapped around the support. Alternatively, a swinging type of support can be used and the support strap, protected with felt or lagging, must be securely fixed to the pipe.

Fixed Supports

A fixed support rigidly connects the pipeline to a structure totally restricting movement in at least two planes of direction. Such a support can be used to absorb moments and thrusts.

Placement of Supports

Careful consideration should be given to the layout of piping and its support system. Even for non-pressure lines the effects of thermal expansion and contraction have to be taken into account. In particular, the layout should ensure that thermal and other movements do not induce significant bending moments at rigid connections to fixed equipment or at bends or tees.

For solvent-cement jointed pipe any expansion coupling must be securely clamped with a fixed support. Other pipe clamps should allow for movement due to expansion and contraction. Rubber-ring jointed pipe should have fixed supports behind each pipe socket.

Setting of Pipes in Concrete

When PVC pipes are encased in concrete, certain precautions should be taken:

- Where damage to the pipes could occur as a result of movement relative to the surrounds, pipes should be fully wrapped with a compressible material, such as felt, with a minimum thickness of 5% of the pipe diameter, i.e. 5 mm for a 100 mm diameter pipe.

-

Alternatively, flexible (rubber ring) joints should be provided at entry to and exit from the concrete as shown. This procedure also allows for possible differential movement between the pipeline and concrete structure.

It must be borne in mind, however, that without a compressible membrane; stress transfer to the concrete will occur and may damage the concrete section.

- Expansion joints coinciding with concrete expansion joints should be provided to accommodate movement due to thermal expansion or contraction in the concrete.

Anchorage at Fittings

It is advisable to rigidly clamp at valves and other fittings located at or near sharp directional changes, particularly when the line is subjected to wide temperature variations.

With the exception of solvent-cement jointed couplings, all PVC fittings should be supported individually and valves should be braced against operating torque.

Thrust Anchorage

A solvent-cement jointed PVC pipeline will not usually require thrust anchorage, but the designer should take into consideration any stress on the fittings. As pipe diameter or working pressure increases it is good practice to install thrust anchors where necessary. A rubber-ring jointed pressure pipeline requires anchorage at all joints, at changes in direction and at other positions where unbalanced pressure forces exist.

Expansion Joints

For above-ground installations with solvent cement joints provision should be made in the pipeline for expansion and contraction. If the ends are constrained and there is likely to be significant thermal variation, then a rubber ring joint should be installed at least every 12 m to allow for movement within the pipeline.

Support Spacing

The spacing of supports for a PVC pipeline depends on factors such as the diameter of the pipe, the density of the fluid being conveyed and the maximum temperature likely to be reached by the pipe material.

Non-Pressure Pipes

The table below, from AS/NZS 2032, shows the support spacing in metres for PVC non-pressure pipe. These spacing may need to be reduced for pipes exposed to direct sunlight or where increased pipe material temperature may occur. For more information, see AS/NZS 2032.

Recommended Maximum Spacing of Supports for all Classes of PVC Non-Pressure Pipe

| Size DN | Maximum Support Spacing | |

| Horizontal (m) | Vertical (m) | |

| 32 | 0.9 | 1.8 |

| 40,50 | 1.0 | 2.0 |

| 65 – 150 | 1.2 | 2.5 |

| >150 | 1.5 | 3.0 |

Pressure Pipes

The table below, from AS/NZS 2032, shows the support spacing in metres for PVC pipe carrying water at 20°C. These spacings do not allow for additional extraneous loadings. These spacings are also acceptable for PVC-O and PVC-M pipes. However, for the same class of pipes, PVC-O and PVC-M will show increased deflection between the supports. Since deflections are very small, this increase will not usually be of functional significance.

Recommended Maximum Spacing of Supports for all Classes of PVC Pressure Pipe for Water

| Size DN | Maximum Support Spacing | |

| Horizontal (m) | Vertical (m) | |

| 15 | 0.6 | 1.2 |

| 20 | 0.7 | 1.4 |

| 25 | 0.75 | 1.5 |

| 32 | 0.85 | 1.7 |

| 40 | 0.9 | 1.8 |

| 50 | 1.05 | 2.1 |

| 65 | 1.2 | 2.4 |

| 80 | 1.35 | 2.7 |

| 100 | 1.5 | 3 |

| 125 | 1.7 | 3.4 |

| 150 | 2 | 4 |

| 175 | 2.2 | 4.4 |

| 200 | 2.3 | 4.6 |

| 225 | 2.5 | 5 |

| 250 | 2.6 | 5.2 |

| 300 | 3 | 6 |

If temperatures are in excess of 20°C the horizontal spacing should be reduced by 25% for every 10°C above 20°C. At 60°C, continuous horizontal support is required.

Vertical Installation

Generally, vertical runs are supported by spring hangers and guided with rings or long U-bolts which restrict movement of the rise to one plane. It is sometimes helpful to support a long riser with a saddle at the bottom.

Where a PVC pipeline is to pass through or is to be built into a floor or wall of a building, allowance should be made for it to move without shearing against any hard surfaces or without causing damage to the pipe or fittings.

An annular space of not less than 6 mm should be left around the pipe or fitting. This clearance should be maintained and sealed with a flexible sealant such as loosely packed felt, a rubber convolute sleeve or other suitable flexible sealing material.

If the pipeline has to pass through a fire-rated wall, appropriate fire stop collars should be installed.

When a fire breaks out, the fire stop collar will expand and seal off the pipe, thus preventing fire from spreading by means of the pipe access hole. Because fire stop collars seal off the pipe they must not be used on the water supply lines required for fire fighting.

Protection from Solar Degradation

Although PVC pipe can be installed in direct sunlight, it will be affected by ultra-violet light which tends to discolour the pipe and can cause a loss of impact strength. No other properties are impaired. If the pipe is to be installed in continuous direct sunlight, it is advisable to paint the exterior with a white or light-coloured water-based paint.