Stub Flanges for PVC pipe (VX-TN-5E)

Introduction

Flanged joints in pipelines are used to create a demountable joint for future disassembly to connect valves and vessels, where strength in tension is required or to joint to other materials.

Vinidex has, for a number of years, supplied a complete range of Full Face Flanges. These flanges were accompanied with a galvanised metal Backing Plates.

A range of Stub Flanges are available incorporating a PVC backing ring. These fittings are manufactured to Series 1, PN18 in accordance with Australian Standard AS/NZS 1477. The system eliminates the traditional steel backing ring and replaces it with a sturdy structural PVC Flange Plate making the joint lightweight and corrosion resistant.

The purpose of this note is to create awareness of the care and installation of Stub Flanges and should be read in conjunction with Australian Standards AS/NZS 2032 -Installation of PVC pipe systems.

Product Information

The PVC Stub Flange and PVC Flange Plates are sold and coded as one unit. Vinidex PVC Flange Plates are supplied with moulded bolt holes that are compatible with both Table D and Table E in accordance with AS 2129.

Table 1

| Nominal Size DN | PVC Stub Flange & PVC Backing Plate Product Code | Mass (kg) |

| 50 | 35651 | 0.39 |

| 80 | 35671 | 0.65 |

| 100 | 35681 | 1.02 |

| 150 | 35701 | 2.12 |

Assembly

Preparation prior to assembly will be a key function to a successful installation.

Prior to installation a number of checks need to be carried out:

- Ensure the sealing faces of both the Stub Flange and the mating surface are flat, clean and with no evidence of burrs or notches.

- When jointing flange to flange, check the size and number of the nuts and bolts are in accordance with AS2129, Table D or Table E.

- When determining the bolt length, consideration should be given to the thickness of the PVC Flange Plate. Thicknesses of PVC Flange Plates are shown in Table 2 below.

- Check that the nuts and bolts easily screw together and have sufficient thread to enable the sealing surfaces to meet and to be tensioned.

- Place Flange Plate on the pipe in readiness for jointing, ensuring the ribbed side of the Flange Plate is facing the Stub Flange.

- Having cut the pipe to the correct length, prepare the pipe end and the socket of the Stub Flange for solvent cementing to each other. The preparation and the solvent cement joint are to be executed in accordance with AS/NZS 2032.

With the Flange Plate held captive on the pipe, the following steps are mandatory.

- Washers to be placed under the heads of all bolts and nuts to spread the force and prevent damage to the Flange Plate.

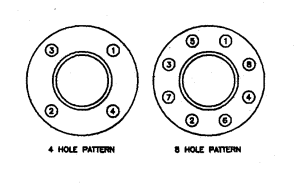

- Tighten bolts gradually by pulling down the nuts diametrically opposite each other using a torque wrench to ensure even loading around the bolt heads and nuts. (See below).

- Tighten each bolt several times repeating the process pattern.

- The final recommended torque value for Stub Flange bolts are shown in Table 2.

Table 2

| Nominal Size DN | Thickness (mm) | Torque Value (Nm) |

| 50 | 24.0 | 50 |

| 80 | 28.0 | 50 |

| 100 | 31.0 | 50 |

| 150 | 36.0 | 65 |

Alignment

Alignment of the Stub Flange to the mating flange should be installed with the normal installation tolerance in accordance with Australian Standards AS/NZS 2032.

The Stub Flange joint should be completed and allowed to cure prior to torquing the flange bolts. Premature torquing of the bolts will cause movement of the joint and weaken the joint itself.

External use of Stub Flanges

Stub Flanges, like any other PVC fittings are not designed for exposure to direct sunlight and should be painted with PVA, light coloured paint or be otherwise protected.

Pressure Testing

Upon completion, the system should be pressure tested in accordance with Australian Standard AS/NZS 2032.

As the Stub Flange is solvent cemented to the pipe, the system should not be pressure tested until at least 24 hours after the last joint has been made.

References

- Australian standard AS/NZS 2032 – Installation of PVC Pipe Systems