PE Relining and Sliplining

Vinidex PE pipes have the chemical resistance properties and longitudinal flexibility to provide an ideal solution for relining existing corroded or damaged pipelines in water supply, sewers, and drain applications.

Existing pipelines used to transport aggressive and dangerous fluids may be restored by relining techniques, and cost-effective solutions are provided by eliminating the need for open cut trenches in urban and heavily built up areas. Installations can be planned around off-peak traffic periods to minimise disruption and reduce installation times.

Existing pipelines can be renovated by inserting Vinidex PE pipes into the old pipes. Insertion pipes can be pulled into position by mechanical winches.

Although insertion of the PE pipes will reduce the internal diameter of the pipeline, the effective flow capacity of the renovated line may in fact be greater than the existing installation due to the improved pipe wall friction factors of PE as compared to the existing pipe with heavily corroded or damaged internal surfaces. Inspection of the existing line should be performed by CCTV to provide data as to the actual likely flow friction factors.

Relining with PE pipes provides a structural element that is capable of withstanding either internal pressure or external loading without relying on the residual strength of the original degraded pipe elements.

PE Sliplining Trench Opening

The PE pipes require short length inlet and exit trenches to accommodate the PE pipe radius to lead into the existing pipeline, and the winch assembly used to pull the PE liner along the pipeline. The minimum bending radius of the PE liner is dependent on the SDR.

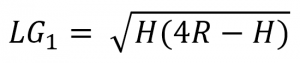

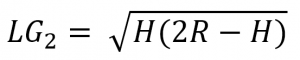

The dimensions of excavations required for slip lining are:

- Where the PE insert pipe is on the natural surface level

- Where the PE insert pipe is at a height H above the natural surface level

where:

Grouting

Grouting of the gap between the outside diameter of the PE liner, and the inside of the existing pipe is necessary only when the original pipe has been damaged to the extent that there is no residual external load capacity, or where manhole connections cannot be sealed off to prevent groundwater infiltration.

Where grouting is applied, the pressure should not exceed 50 kPa, and depending on the PN rating of the PE liner pipe, external collapse calculations should be carried out. Where cement-based grouts are used, the temperature rise in the PE liner due to the heat of hydration must be taken into account.

The PE liner pipes may be filled with water prior to grouting to increase the external pressure resistance, and to provide additional line weight to prevent the PE liner pipe floating during grouting and losing the final grade line.

Excavation

Sliplining existing pipes using Vinidex PE pipes allows for a reduction of excavation in built up areas.

Only the excavation necessary to feed the PE liner pipe into the existing line is required and depending on the total length of the line and the location of existing manholes, a liner length of approximately 100 metres may be drawn along the line in each section. For small diameter pipes, the PE can be supplied in Vinidex pipe reels. This allows for a single run of PE to be inserted into existing pipe without the need for intermediate jointing.

Where the existing service cannot be taken out of service, or temporarily blocked off during the relining process, extra excavation may be required to allow for the installation of a temporary diversion line.

Jointing the Liner

Depending on the diameter of the pipe, a single length of PE pipe can be installed to provide a single length of seamless liner.

Larger PE pipes can be butt welded above ground on site to provide a continuous length pipe which can be inspected for joint integrity before installation.

The butt weld process provides a joint which resists longitudinal load and has the same chemical resistance properties as the pipe. The external diameter weld bead sections may be mechanically removed prior to insertion to prevent any possibility of snagging on damaged sections, or protrusions, in the bore of the existing pipe to be relined. Where weld beads are removed, care must be taken not to notch the PE pipe wall. Butt welded joints must be allowed to cool to ambient temperature prior to drawing into the final position so as to prevent any damage to the joint section.

Safe Axial Pulling Loads

Safe Axial Pulling Loads for PE100 pipe

| DN | Safe Axial Pulling Loads (in kN) for PE100 pipe based on a tensile stress of 8MPa | ||||||||

| SDR 41 | SDR33 | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR9 | SDR7.4 | |

| 50 | – | – | – | 2.9 | 3.5 | 4.3 | 5.2 | 6.2 | 7.5 |

| 63 | – | – | 3.7 | 4.5 | 5.7 | 6.9 | 8.3 | 10 | 11.8 |

| 75 | – | 4.2 | 5.3 | 6.5 | 8 | 9.6 | 11.7 | 14.1 | 16.7 |

| 90 | – | 6.1 | 7.6 | 9.3 | 11.5 | 13.8 | 16.9 | 20.3 | 24 |

| 110 | – | 9.1 | 11.4 | 13.9 | 17.2 | 20.7 | 25.1 | 30.2 | 36 |

| 125 | – | 11.9 | 14.5 | 17.9 | 21.9 | 26.8 | 32.5 | 39.1 | 46.4 |

| 140 | 7.3 | 14.7 | 18.3 | 22.4 | 27.5 | 33.6 | 40.6 | 49 | 58.3 |

| 160 | 9.5 | 19.1 | 24 | 29.5 | 35.9 | 44 | 53.4 | 63.9 | 76 |

| 180 | 12 | 24.1 | 30 | 37 | 45.5 | 55.7 | 67.4 | 80.8 | 96.1 |

| 200 | 15.7 | 30.2 | 37.2 | 45.9 | 56.3 | 68.5 | 83.2 | 100 | 118 |

| 225 | 19.4 | 37.8 | 46.8 | 58.1 | 71.3 | 86.9 | 105 | 126 | 150 |

| 250 | 24 | 46.9 | 58 | 71.2 | 87.5 | 107 | 130 | 156 | 185 |

| 280 | 30.3 | 58.7 | 72.4 | 89.8 | 110 | 134 | 163 | 196 | 233 |

| 315 | 38 | 74.4 | 92.1 | 113 | 139 | 170 | 206 | 248 | 294 |

| 355 | 47.4 | 94.3 | 117 | 144 | 177 | 216 | 261 | 314 | 374 |

| 400 | 59.5 | 120 | 148 | 183 | 224 | 274 | 332 | 399 | 474 |

| 450 | 75.7 | 151 | 187 | 232 | 284 | 347 | 421 | 504 | 600 |

| 500 | 96.1 | 186 | 231 | 286 | 350 | 428 | 519 | 623 | – |

| 560 | 121 | 235 | 290 | 358 | 440 | 537 | 650 | 781 | – |

| 630 | 151 | 296 | 367 | 452 | 556 | 679 | 823 | 989 | – |

| 710 | 188 | 377 | 467 | 576 | 707 | 863 | 1046 | 1257 | – |

| 800 | 238 | 478 | 592 | 730 | 897 | 1095 | 1326 | 1595 | – |

| 900 | 303 | 605 | 748 | 924 | 1138 | 1387 | 1680 | – | – |

| 1000 | 384 | 746 | 923 | 1142 | 1402 | 1690 | 2062 | – | – |

| 1100 | 485 | 895 | 1109 | 1380 | 1686 | 2046 | – | – | – |

| 1200 | 601 | 1073 | 1331 | 1643 | 1932 | 2465 | – | – | – |