Chemical Resistance of PE Pipes

The outstanding resistance of Vinidex polyethylene systems to a variety of chemical reagents, allows their use in a wide range of chemical processes. Chemical resistance of polyethylene is due to the non-polar or paraffinic nature of the material and is a function of reagent concentration and temperature. Some attack may occur under specific conditions however, use of Vinidex polyethylene systems provides a cost effective solution when the behaviour of polyethylene is compared to that of alternative materials.

Where PE pipe is used for water and wastewater applications users should refer to the PIPA Industry Guideline POP201 – Resistance of Plastic Pipes and Fittings to Water and Wastewater Chemicals which was prepared in conjunction with the Water Services Association of Australia.

For PE pipes conveying disinfected drinking water, the type and concentration of disinfectant residual in conjunction with other operating factors such as temperature and stress can potentially reduce expected service life if these factors are not considered in pipe selection. Chlorine-based disinfectants are oxidising agents. PE resin compounds contain stabilising additives that provide resistance against the oxidative effects of these chemicals under typical operating conditions.

For chlorine and chloramine disinfected systems at temperatures up to of 21°C and maintained within the aesthetic limits of the Australian Drinking Water Guidelines*, the expected life of SDR11 PE 100 and PE80 is not adversely affected. However, where higher temperatures are coupled with more aggressive oxidative environments, PE pipe performance may be compromised. For guidance refer to PIPA Industry Guideline POP018* or contact Vinidex.

Elevated temperatures and higher chlorine disinfectant levels may reduce the service life of PE drinking water services under normal operating mains pressures. The critical combinations of these conditions, along with other risk factors are outlined in PIPA POP018.

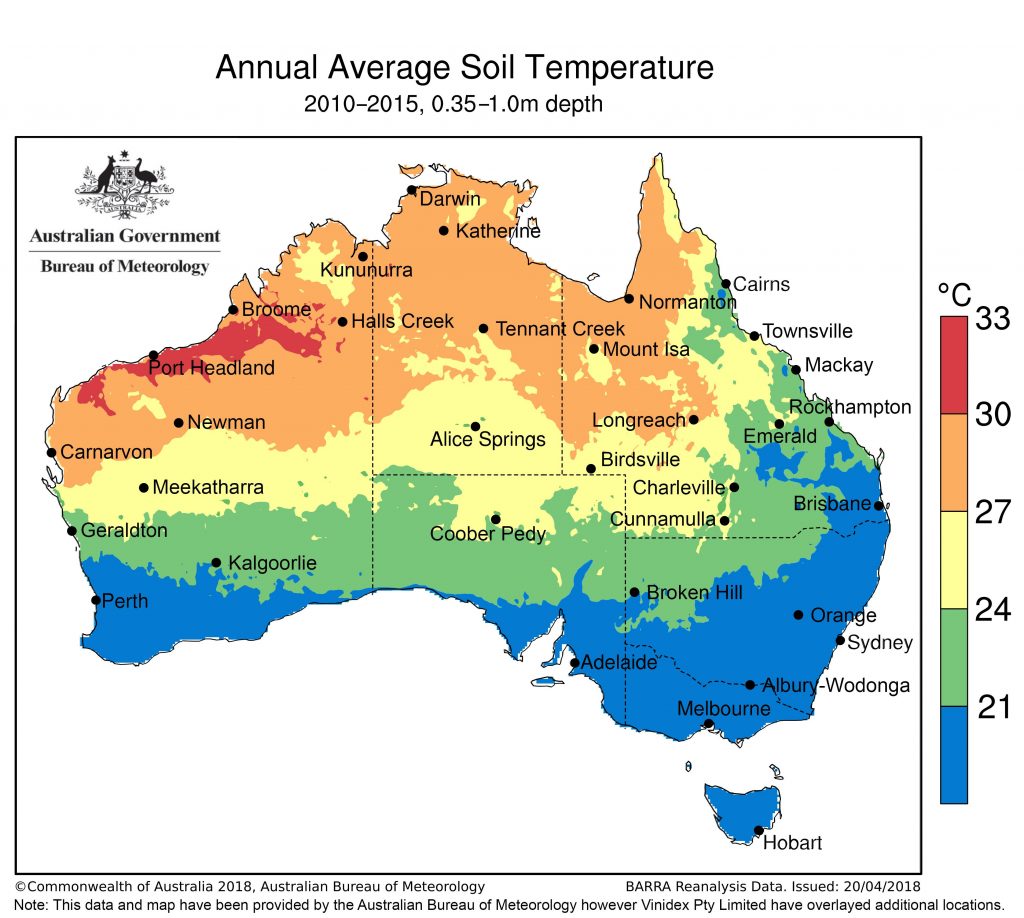

The suitability of water services installed using conventional PE100 (with a CC1 classification) can be determined in part by the map below indicating typical soil temperatures and knowledge of the chlorine level in the water.

Due to elevated soil (and water) temperatures PIPA POP018 indicates that a reduced service life is more likely to occur where the soil/water temperatures fall into the red, orange and yellow zones plus the areas around Townsville on the map.

Recognising the increased risk in the above zones Vinidex has introduced Chlorblue® with a higher chlorine resistance classification (CC2). Link to Chlorblue page:

Chlorblue® is suitable for a much wider combination of operating temperatures and chlorine disinfectant levels and can be used for most water chemistries in the majority of temperature zones

Chlorblue® is the preferred choice for use in applications where the fluid being transported has an elevated level of chlorine and temperature

For water service applications where chlorine disinfectant is not used, Vinidex offers Black PE100. Normal de-rating guidelines for elevated temperature should be followed.

For red, orange, yellow zones and areas around Townsville, please click here for selection of alternative products to existing blue stripe

Vinidex PE pipes should not be used to convey water disinfected with Chlorine Dioxide as this will deplete the antioxidant additives in the material. For more information refer to PIPA Technical Note TN008*.

Where rubber modified LDPE blends are used for improved ESCR properties in irrigation applications, the effect of specialty chemicals may require evaluation e.g. micro-irrigation tube/dripper tube.

General Effect of Chemicals on Polyethylene Pipe

- Resistant: Water, solutions of inorganic salts, weak acids, strong organic acids, strong alkaline solutions, aliphatic hydrocarbons.

- Has adequate resistance: Strong acids, hydrofluoric acids, fats and oils.

- Has limited resistance: Lower alcohols, esters, ketones, ethers, aromatic hydrocarbons, mineral oil.

- In most cases non-resistant: Light naphtha, fuel mixture.

- Completely non-resistant: Unsaturated chlorinated hydrocarbons, turpentine.

Chemical Resistance Table for Polyethylene

Important Information

The listed data are based on results of immersion tests on specimens, in the absence of any applied stress. In certain circumstances, where the preliminary classification indicates high or limited resistance, it may be necessary to conduct further tests to assess the behaviour of pipes and fittings under internal pressure or other stresses.

Variations in the analysis of the chemical compounds as well as in the operating conditions (pressure and temperature) can significantly modify the actual chemical resistance of the materials in comparison with this chart’s indicated value.

It should be stressed that these ratings are intended only as a guide to be used for initial information on the material to be selected. They may not cover the particular application under consideration and the effects of altered temperatures or concentrations may need to be evaluated by testing under specific conditions. No guarantee can be given in respect of the listed data. Vinidex reserves the right to make any modification whatsoever, based upon further research and experiences.

For resistance information on specific chemicals see Chemical Performance of PE pipes (PDF).

Chemical Resistance of Joints

Fusion Joints (PE)

Fusion joints include those made by butt fusion, electrofusion and socket fusion and these types will have the same chemical resistance as listed for PE.

Rubber Ring Joints (Elastomers)

Chemical resistance of Rubber Ring Joints may be assessed by reference to Chemical Resistance of Elastomers.

Other Fittings

PE pipe systems often employ fittings and accessories manufactured from materials dissimilar to the pipe material, such as brass, aluminium, iron and polypropylene. In such cases, the designer should refer to the appropriate manufacturer for advice on the chemical resistance of these materials.

References

* NRMMC, “Australian Drinking Water Guidelines 6 2011 Version 3.4 updated October 2017, National Water Quality Management Strategy.”, National Health and Medical Research Council, National Resource Management Ministerial Council, Commonwealth of Australia, Canberra, 2017.